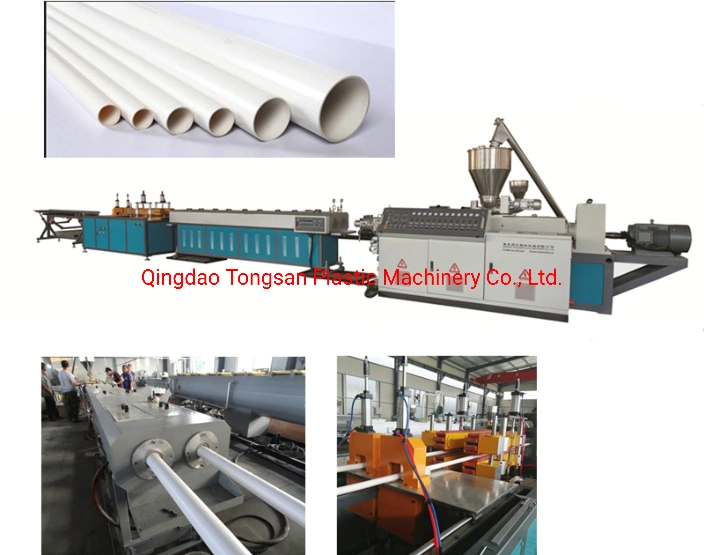

It is mainly used to produce all kinds of UPVC pipes for agricultural water supply and drainage, building water supply and drainage and cable laying, etc.

Saw cutter and planetary cutter for choice

Changing some parts can also produce M-PVC pipe, C-PVC pipe, inner spiral wall pipe, inner hollow wall pipe, formed core pipe.

Conical twin screw extruder and parallel twin screw extruder for choice

Double-strand and four-strand for choice for small pipes

1. Process flow:

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould → vacuum calibration machine → haul off machine → cutting machine → stacker or automatic belling machin

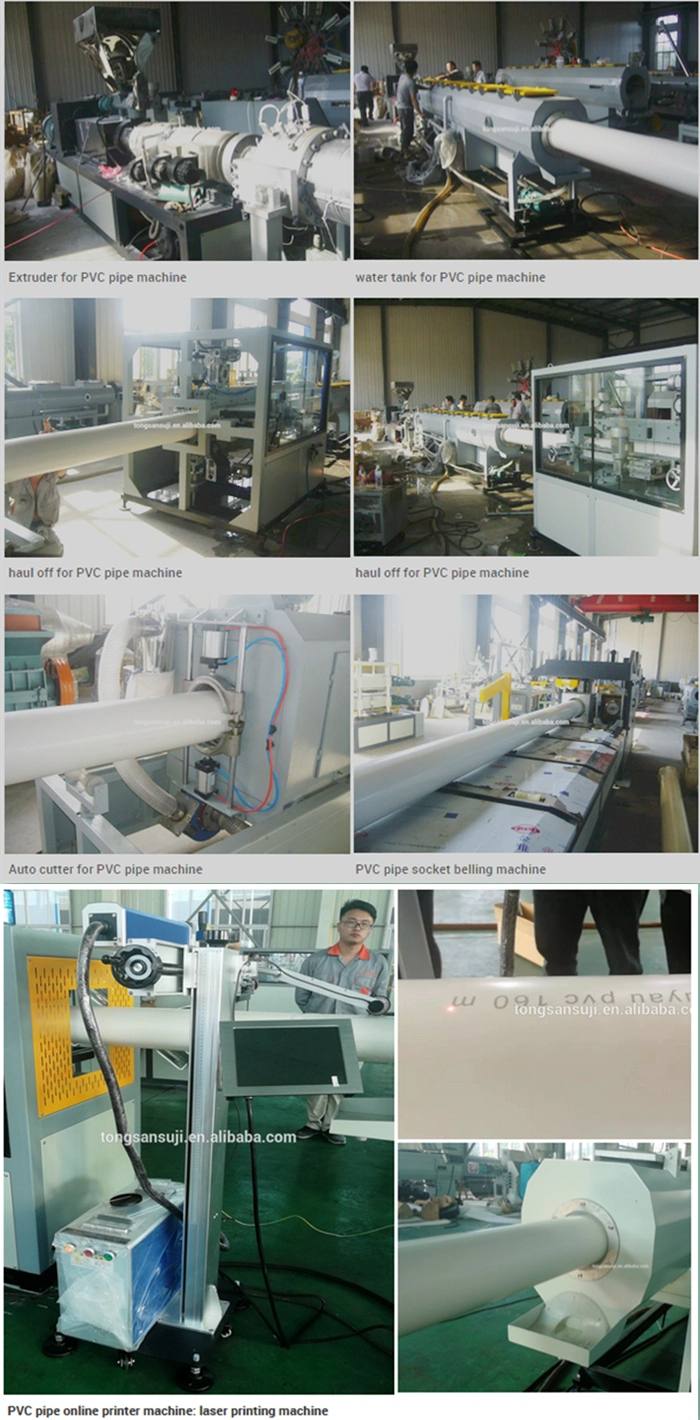

1.Conical twin screw extruder

2.Die head. Due to the diameter, it can be single, double and four die head

3.Vacuum tank: due to diameter, it can be designing of single, double vacuum chambers

4.Haul-offs: due to diameter, it can be designing of double, three, four, six, eight caterpillars

5.Cutter: due to diameter, it can be designing of saw cutter or planetary cutter

6.stacker or automatic belling machine

2. Main parameter of pvc pipe plastic machine

Mode

| Pipe range (mm) | extruders

| Max. output (kg/h) | Max. speed (m/min) | Total power (kw) | Line length (m) |

PVC-50x2 | 16-50 | SJSZ51/105 | 150 | 6m | 60w | 20m |

PVC-63 | 16-63 | SJSZ55/125 | 120 | 10m | 45w | 20m |

PVC-110 | 50-110 | SJSZ65/132 | 150 | 6m | 60w | 24m |

PVC-160 | 63-160 | SJSZ65/132 | 300 | 5m | 100w | 24m |

PVC-250 | 110-250 | SJSZ80/156 | 400 | 3.5m | 120w | 28m |

PVC-315 | 160-315 | SJSZ 80/156 | 400 | 3m | 160w | 28m |

PVC-450 | 250-450 | SJSZ 92/188 | 700 | 1.5m | 200w | 36m |

PVC-630 | 315-630 | SJSZ92/188 | 700 | 0.9 | 230kw | 36m |

3,Machine list

No. | Equipment list for PVC pipe manufacturing plant | Quantity |

1 | Mixing machine | 1 set |

2 | Auto feeder | 2 sets |

3 | Conical double screw extruder | 1 set |

4 | Die head and sizing mold | customized |

5 | 1st cooling tank | 1 set |

6 | 2nd cooling tank | 1 set |

7 | haul off device | 1 set |

8 | auto cutting machine | 1 set |

9 | Laser printer or ink jet printer | 1 set |

10 | PVC pipe stacker | 1 set |

11 | PVC pipe joint belling machine | 1 set |

12 | Crushing machine | 1 set |

13 | PVC powder milling machine | 1 set |

14 | Air compressor | 1 set |

15 | water chiller | 1 set |

PVC /UPVC pipe application

About PVC PIPE

PVC pipes (divided into PVC-U pipes, PVC-M pipes and PVC-O pipes) Rigid polyvinyl chloride pipes are made of polyvinyl chloride resin, stabilizers, lubricants, etc., and then extruded by hot pressing. The first plastic pipe to be developed and applied.

PVC-U pipe has strong corrosion resistance, easy bonding, low price, and hard texture. However, due to the seepage of PVC-U monomer and additives, it is only suitable for water supply systems whose conveying temperature does not exceed 45ºC. Plastic pipes are used for drainage, waste water, chemicals, heating and cooling fluids, food, ultra-pure liquids, mud, gas, compressed air and vacuum systems.

PVC-O pipe, Chinese name biaxially oriented polyvinyl chloride, is the latest evolutionary form of PVC pipe. The pipe manufactured through a special oriented processing process will use the extrusion method to produce the PVC-U pipe for axial stretching and diameter Stretching to make the long-chain PVC molecules in the pipe arranged biaxially, to obtain a new type of PVC pipe with high strength, high toughness, high impact resistance and fatigue resistance.

1. It has good tensile and compressive strength: but its flexibility is not as good as other plastic pipes.

2. Low fluid resistance: The wall of PVC-U pipe is very smooth and has little resistance to fluid. Its roughness coefficient is only 0.009. Its water delivery capacity is 20% higher than that of cast iron pipes of the same diameter and 40% higher than that of concrete pipe %.

3. Excellent corrosion resistance and chemical resistance: PVC-U pipes have excellent acid resistance, alkali resistance, and corrosion resistance, and are not affected by damp water and soil pH. No anti-corrosion treatment is required when laying pipes.

4. It has good water tightness: the installation of PVC-U pipes, whether by bonding or rubber ring connection, has good water tightness.

5. Anti-bite: PVC-U tube is not a source of nutrition, so it will not be corroded by rodents. According to a test conducted by the National Sanitation Foundation in Michigan, rats will not bite PVC-U pipes.

6. Performance test: curing time, shrinkage, splitting strength, tensile performance, peeling strength, thermal stability, pot life, storage period, release of harmful substances.

Disadvantages of pipe

1. Not suitable for hot water pipes, but not suitable for direct drinking water supply pipes.

2. Easily brittle when impacted.

3. Some low-quality counterfeit UPVC pipes have plasticizers added in their production, which can cause media pollution and greatly shorten the aging period of UPVC pipes.

PVC pipes have been used for a long time and chloride ions are precipitated. They are not suitable for tap water pipes. They have poor impact resistance and are not suitable for gas pipes. However, PVC pipes are low in price, high in hardness, and are affected by temperature. Water supply pipes and drainage pipes are used for municipal water supply and drainage, industrial water supply and drainage, civil water supply and drainage, irrigation, and vegetation watering.

The difference between PVC-U and UPVC

PVC-U and UPVC are what we usually call PVC pipes, but the order of writing is different.

In the PVC production process, in order to increase the plasticization performance of PVC and improve production efficiency, plasticizers (such as DOP, DBP, DINP, etc.) will be added, and the PVC products with plasticizers will be softer.

Generally, we refer to PVC products without plasticizers added during processing as UPVC, or PVC-U.

Other products

About our company

Our Customer for corrugated pipe making machines

| Asia | ||||

| Afghanistan | Bahrain | Bangladesh | India | Indonesia |

| Iran | Kuwait | Malaysia | Mongolia | Oman |

| Pakistan | Qatar | Saudi Arabia | SriLanka | Turkey |

| UAE | Vietnamese | Yemen | South Korea | |

| Africa | ||||

| Algeria | Burundi | Cameroon | Botswana | Congo |

| Egypt | Djibouti | Ethiopia | South Africa | Cote Divoire |

| Kenya | Libya | Mali | Mauritius | Morocco |

| Nigeria | Sudan | Tanzania | Tunisia | Uganda |

| Europe | ||||

| Belgium | Bulgaria | Poland | Belarus | Georgia |

| Kazakhstan | Kyrgyzstan | Uzbekistan | Tajikistan | Turkmenistan |

| Ukraine | Lithuania | |||

| America | ||||

| Chile | Colombia | Dominica | Ecuador | Mexico |

| Peru | Uruguay | Venezuela | ||

Our advantage

A.22 years manufacturer for plastic extruder machines,

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of machine quality

Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for the after-sell service.

Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and keeping up with the times.

FAQ

1. Why choose us

We are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction.

We only choose qualified supplier -- Tongsan excellent partner

We work closely with world famous brand,your equipment can also be equipped with any famous brand as you wish,such as Siemens motor,ABB inventer,Omron temperature controller, Schneider electric devices,etc.

2. What service do we provide?

Perfect service system:

1.We will provide the Feasibility Analysis Report for your project.

2.We will provide the model selection and technical parameter of our machinery.

3.We will provide the design for the plant and electric power accounting for the facilities.

4.We will provide the design for plastic formula according to the products requirement.

5.We will provide the technology of plastic product surface treatment if need.

6.We will provide technique training for your operator.

7.We will provide solution for the production problem .

8.We will install and test the machine in customer's factory.

9.We will provide turnkey project to customers.

3. Payment terms

30% of the total amount should be paid by wire transfer as a down payment, and the balance (70% of the total amount) should be paid (at sight) before the delivery of the wire transfer or irrevocable letter of credit

4. Delivery terms:

4.1 Delivery terms: FOB Qingdao Port.

4.2 Delivery deadline: within 30-60 working days after receiving the advance payment, the seller shall notify the buyer to inspect. The seller should complete the packaging of the goods within 15 working days after receiving the full payment and be ready for shipment.

4.3 Supervised loading: The seller should inform the buyer of the exact loading time, and the buyer should arrange the scope of supervised loading.

5. Warranty terms:

5.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

5.2 The seller shall guarantee that the service and spare parts are free of charge during the entire equipment warranty period.

5.3 LIFELONG service: After the 12-month warranty, the seller shall provide LIFELONG service for the sold goods, and the buyer shall pay for the required spare parts.

6. Inspection :

After the machine is completed, the seller should notify the buyer to inspect before delivery, and the seller guarantees that all the goods sold are of good quality. The seller does not bear the material cost of the machine inspection in the seller's factory. The buyer should come to the seller's factory for inspection, or the buyer can invite any third party to enter the seller's factory for inspection.

7. Installation and equipment debugging:

If the buyer needs it, the seller should send a team of technicians to the buyer's factory for full-line operation of installation and testing, and the buyer should lift the price of the entire food/location and group purchase information (aircraft, food, hotel, etc.), and charge the engineer 100 USD/day/engineer's cost.